News

Pyrowave Successfully Demonstrates the Carbon Footprint Reduction of it’s Michelin Plastic Recycling Project in France

2023-04-16 / News

Pyrowave Successfully Demonstrates the Carbon Footprint Reduction of it’s Michelin Plastic Recycling Project in France

The Company Unveils Life Cycle Analysis at Go Circular

Rotterdam, April 20, 2023 — At the Go Circular plastic circularity conference in Rotterdam, Netherlands, Pyrowave will unveil today the results of the environmental assessment of a project carried out with Michelin in France to recycle plastic waste back into its basic constituent, the styrene monomer, to be used in the manufacture of sustainable tires. The methodology developed to assess the project is the result of a two-year effort to meet the highest standards of environmental communication.

“Chemical recycling of plastics encompasses multiple technologies with varying environmental impacts. Our initial goal was to establish a robust and transparent peer-reviewed approach to assessing the environmental impact of our technology in a real-life project, while also being able to compare different technologies on common metrics”, stated Virginie Bussières, Vice President, Communications, Government Relations and Marketing at Pyrowave. “Our approach will help assess and highlight the impact of each step of the plastic recycling value chain. It provides relevant insights to be shared and discussed”, she added.

Results Driving Collaboration and Continuous Improvement

Our approach helps measure both the contribution of Pyrowave’s technology and of the recycling value chain upstream (including transportation, collection, sorting and preparation of raw materials) and downstream (including transportation, and end-of-life product and by-product management). By categorizing greenhouse gas (GHG) emissions into direct emissions (Scopes 1 and 2) and indirect emissions (Scope 3), we can isolate chemical recycling technology impacts independently from value chain impacts, which are common to all technologies.

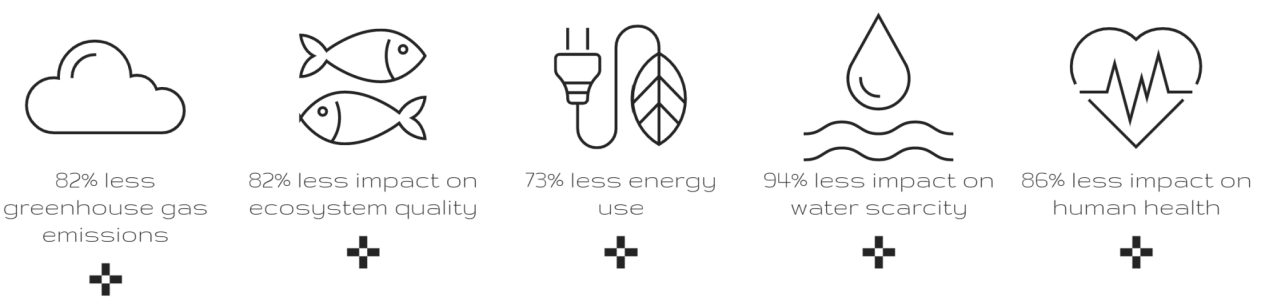

For example, when targeting the impacts associated with Pyrowave’s chemical recycling technology alone (Scopes 1 and 2), there is an 82% GHG-emission reduction and a 73% energy-consumption reduction using recycled plastic waste rather than fossil material to make the same product.

Our methodology also shows that 88% of total climate impacts of the Michelin project originate from the value chain, mostly due to waste sorting and rejects management at the sorting centre, in addition to the recovery of co-products from the process. These key figures highlight the importance of reducing sorting rejects and finding sustainable uses for depolymerization co-products beside thermal valorisation, the scenario considered in the study. To reach this goal, investments to improve sorting efficiency or to promote eco design of packaging are potential solutions to reduce sorting rejects and improve the overall recycling environmental performance. For by-products recovery from chemical recycling technologies, the approach can lead to collaborations with industry partners to find high-value applications, to keep our precious resources in the manufacturing loop.

Popularizing Science to Facilitate Sharing

In the coming years, industries will increasingly use environmental assessment tools to comply with emerging regulatory requirements and to effectively communicate with their customers. Pyrowave has developed a simplified toolbox, available in the Sustainability section of its website, to expand transparent and fact-based discussions. It contains a video for the public, a technical report, a methodological sheet, and a form to access the methodological data file, a first in the industry.

“We frequently hear that data is confidential and competitive in nature, but we believe that increased transparency leads to informed and positive changes in regulatory and economic decisions to fast-track plastic circularity. Our industry’s credibility relies on it”, concluded Virginie Bussières.

About Pyrowave

Pyrowave a pioneer in low carbon microwave electrification of chemical processes. Pyrowave is also a leader in the plastics circular economy and microwave chemical recycling that restores post-consumer and post-industrial plastics into new plastics, returning these resources to their full value to address the global plastics recycling challenge. www.pyrowave.com

-30-

Contact

Virginie Bussières

Vice President, Communications, Government Relations and Marketing

Pyrowave

Vbussieres@pyrowave.com

Cell.: 1-514-978-8580

The Company Unveils Life Cycle Analysis at Go Circular

Rotterdam, April 20, 2023 — At the Go Circular plastic circularity conference in Rotterdam, Netherlands, Pyrowave will unveil today the results of the environmental assessment of a project carried out with Michelin in France to recycle plastic waste back into its basic constituent, the styrene monomer, to be used in the manufacture of sustainable tires. The methodology developed to assess the project is the result of a two-year effort to meet the highest standards of environmental communication.

“Chemical recycling of plastics encompasses multiple technologies with varying environmental impacts. Our initial goal was to establish a robust and transparent peer-reviewed approach to assessing the environmental impact of our technology in a real-life project, while also being able to compare different technologies on common metrics”, stated Virginie Bussières, Vice President, Communications, Government Relations and Marketing at Pyrowave. “Our approach will help assess and highlight the impact of each step of the plastic recycling value chain. It provides relevant insights to be shared and discussed”, she added.

Results Driving Collaboration and Continuous Improvement

Our approach helps measure both the contribution of Pyrowave’s technology and of the recycling value chain upstream (including transportation, collection, sorting and preparation of raw materials) and downstream (including transportation, and end-of-life product and by-product management). By categorizing greenhouse gas (GHG) emissions into direct emissions (Scopes 1 and 2) and indirect emissions (Scope 3), we can isolate chemical recycling technology impacts independently from value chain impacts, which are common to all technologies.

For example, when targeting the impacts associated with Pyrowave’s chemical recycling technology alone (Scopes 1 and 2), there is an 82% GHG-emission reduction and a 73% energy-consumption reduction using recycled plastic waste rather than fossil material to make the same product.

Our methodology also shows that 88% of total climate impacts of the Michelin project originate from the value chain, mostly due to waste sorting and rejects management at the sorting centre, in addition to the recovery of co-products from the process. These key figures highlight the importance of reducing sorting rejects and finding sustainable uses for depolymerization co-products beside thermal valorisation, the scenario considered in the study. To reach this goal, investments to improve sorting efficiency or to promote eco design of packaging are potential solutions to reduce sorting rejects and improve the overall recycling environmental performance. For by-products recovery from chemical recycling technologies, the approach can lead to collaborations with industry partners to find high-value applications, to keep our precious resources in the manufacturing loop.

Popularizing Science to Facilitate Sharing

In the coming years, industries will increasingly use environmental assessment tools to comply with emerging regulatory requirements and to effectively communicate with their customers. Pyrowave has developed a simplified toolbox, available in the Sustainability section of its website, to expand transparent and fact-based discussions. It contains a video for the public, a technical report, a methodological sheet, and a form to access the methodological data file, a first in the industry.

“We frequently hear that data is confidential and competitive in nature, but we believe that increased transparency leads to informed and positive changes in regulatory and economic decisions to fast-track plastic circularity. Our industry’s credibility relies on it”, concluded Virginie Bussières.

About Pyrowave

Pyrowave a pioneer in low carbon microwave electrification of chemical processes. Pyrowave is also a leader in the plastics circular economy and microwave chemical recycling that restores post-consumer and post-industrial plastics into new plastics, returning these resources to their full value to address the global plastics recycling challenge. www.pyrowave.com

-30-

Contact

Virginie Bussières

Vice President, Communications, Government Relations and Marketing

Pyrowave

Vbussieres@pyrowave.com

Cell.: 1-514-978-8580

Share on: