News

Researchers in action - A robot revolutionizing molecular

2023-07-06 / News

In the exciting world of scientific research, collaborations between universities and innovative technology companies can give rise to remarkable breakthroughs. For a company like Pyrowave, which is paving the way for disruptive technologies, the technical challenges encountered sometimes call for unique solutions!

The partnership between Polytechnique Montréal and Pyrowave to model the behavior of molecules in a microwave reactor is already bearing fruit thanks to a new ally: the COBOT, a robotic arm that measures an infinite amount of data without ever tiring.

The research project, which began 3 years ago, aims to understand phenomena that are at the root of many questions in the scientific field: the complex mechanisms in a microwave reactor that enable polystyrene to be returned to its original state, identical to the virgin product derived from fossil matter.

Pyrowave's patented technology has a considerable environmental and economic advantage for many industries, as microwaves are powered by electricity, a source of energy that can be renewable and clean, as well as being more efficient than traditional chemical processes. The research project will optimize the technology and increase its potential many-fold.

This approach is revolutionary and requires the development of new laboratory instruments, such as a robotic ally!

Opening up the black box!

The polystyrene that Pyrowave recycles is in liquid form in the reactor, and liquid polystyrene is a very special fluid. Bruno Blais, the associate professor at Polytechnique Montréal piloting the project, explains that it's a fluid with a texture similar to honey when not stirred, but it liquefies like water when stirred.

Normally, high-speed cameras are used to capture fluid characteristics and generate data that can then be used to create digital models. However, this technique is impossible to use in research: the imposing microwave reactor is opaque, and so is the fluid! The research team was faced with a unique problem, requiring a unique solution.

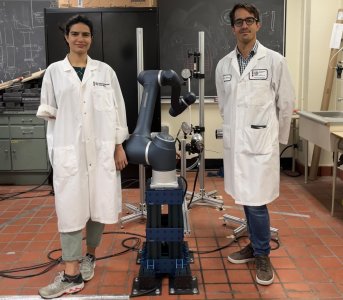

Professor Bruno Blais is accompanied by Ghazaleh Mirakhori, whose doctorate relates to the research project, and Professor Jamal Chaouki. Several interns have also contributed to the project.

A six-axis revolution

To succeed in 'taking pictures' inside the reactor, the team first drew inspiration from a technique developed at Polytechnique Montréal in the 1990s, known as radio active particle tracking. This technique was developed in part thanks to the contribution of Jocelyn Doucet, Pyrowave's CEO, during his doctoral project.

It works in a similar way to a GPS system: researchers calculate the position of a very weakly radioactive ball in a secure space. The data collected is used to build a mathematical model. The bead could then be dropped into the reactor during a test. By tracking its various positions, fluid movements can then be modeled.

However, researchers must manually move the ball to build the model, which limits the accuracy of the data obtained and introduces a significant margin of error.

After extensive testing and collaborative work, the Polytechnique team and Pyrowave came to the conclusion: in the age of artificial intelligence and massive data, why not use them to generate hyper-precise models?

A small revolution in research then emerged from this question: the team acquired a collaborative robot, or COBOT, which makes the movements programmed into it.

The same modeling method can then be performed, but with unrivalled precision. Articulated by six axes, the COBOT can move the ball at will, without ever tiring (or suffering from the heat wave!), and follow any trajectory. So, instead of having thirty or so data points measured by hand, the robot can measure points every 10 milliseconds for several hours, without any human constraints. The huge amount of data generated enables the team to build an infinitely more accurate model and use machine learning to train the artificial intelligence that determines the ball's movements inside the reactor.

Watch the COBOT in action. The video is an accelerated version of a 10-minute test.

The progress made in this project is therefore very encouraging! The technique developed represents a real paradigm shift.

"This makes it possible to achieve a level of precision that was simply unimaginable before. Thanks to this new technique, it is possible to map the movements of particles and fluid inside chemical reactors. This considerably improves the efficiency of chemical reaction processes by providing a better understanding of the exchanges taking place inside. This is a major breakthrough that opens up fascinating new perspectives for the research field."

- Ghazaleh Mirakhori

The future of COBOT in other industries

This first phase, aimed at applying COBOT to a novel methodology, has enabled us to carry out analyses that were previously impossible. The next steps involve fine-tuning the technical details and making COBOT operational in an industrial environment, in particular with Pyrowave reactors.

Professor Blais sees enormous potential in this breakthrough to accelerate the development of new techniques in various industries where opaque reactors are frequently used, such as pharmaceuticals, agri-food and, of course, chemical recycling.

The partnership between Polytechnique Montréal and Pyrowave to model the behavior of molecules in a microwave reactor is already bearing fruit thanks to a new ally: the COBOT, a robotic arm that measures an infinite amount of data without ever tiring.

The research project, which began 3 years ago, aims to understand phenomena that are at the root of many questions in the scientific field: the complex mechanisms in a microwave reactor that enable polystyrene to be returned to its original state, identical to the virgin product derived from fossil matter.

Pyrowave's patented technology has a considerable environmental and economic advantage for many industries, as microwaves are powered by electricity, a source of energy that can be renewable and clean, as well as being more efficient than traditional chemical processes. The research project will optimize the technology and increase its potential many-fold.

This approach is revolutionary and requires the development of new laboratory instruments, such as a robotic ally!

Opening up the black box!

The polystyrene that Pyrowave recycles is in liquid form in the reactor, and liquid polystyrene is a very special fluid. Bruno Blais, the associate professor at Polytechnique Montréal piloting the project, explains that it's a fluid with a texture similar to honey when not stirred, but it liquefies like water when stirred.

Normally, high-speed cameras are used to capture fluid characteristics and generate data that can then be used to create digital models. However, this technique is impossible to use in research: the imposing microwave reactor is opaque, and so is the fluid! The research team was faced with a unique problem, requiring a unique solution.

Professor Bruno Blais is accompanied by Ghazaleh Mirakhori, whose doctorate relates to the research project, and Professor Jamal Chaouki. Several interns have also contributed to the project.

A six-axis revolution

To succeed in 'taking pictures' inside the reactor, the team first drew inspiration from a technique developed at Polytechnique Montréal in the 1990s, known as radio active particle tracking. This technique was developed in part thanks to the contribution of Jocelyn Doucet, Pyrowave's CEO, during his doctoral project.

It works in a similar way to a GPS system: researchers calculate the position of a very weakly radioactive ball in a secure space. The data collected is used to build a mathematical model. The bead could then be dropped into the reactor during a test. By tracking its various positions, fluid movements can then be modeled.

However, researchers must manually move the ball to build the model, which limits the accuracy of the data obtained and introduces a significant margin of error.

After extensive testing and collaborative work, the Polytechnique team and Pyrowave came to the conclusion: in the age of artificial intelligence and massive data, why not use them to generate hyper-precise models?

A small revolution in research then emerged from this question: the team acquired a collaborative robot, or COBOT, which makes the movements programmed into it.

The same modeling method can then be performed, but with unrivalled precision. Articulated by six axes, the COBOT can move the ball at will, without ever tiring (or suffering from the heat wave!), and follow any trajectory. So, instead of having thirty or so data points measured by hand, the robot can measure points every 10 milliseconds for several hours, without any human constraints. The huge amount of data generated enables the team to build an infinitely more accurate model and use machine learning to train the artificial intelligence that determines the ball's movements inside the reactor.

Watch the COBOT in action. The video is an accelerated version of a 10-minute test.

The progress made in this project is therefore very encouraging! The technique developed represents a real paradigm shift.

"This makes it possible to achieve a level of precision that was simply unimaginable before. Thanks to this new technique, it is possible to map the movements of particles and fluid inside chemical reactors. This considerably improves the efficiency of chemical reaction processes by providing a better understanding of the exchanges taking place inside. This is a major breakthrough that opens up fascinating new perspectives for the research field."

- Ghazaleh Mirakhori

The future of COBOT in other industries

This first phase, aimed at applying COBOT to a novel methodology, has enabled us to carry out analyses that were previously impossible. The next steps involve fine-tuning the technical details and making COBOT operational in an industrial environment, in particular with Pyrowave reactors.

Professor Blais sees enormous potential in this breakthrough to accelerate the development of new techniques in various industries where opaque reactors are frequently used, such as pharmaceuticals, agri-food and, of course, chemical recycling.

Share on: